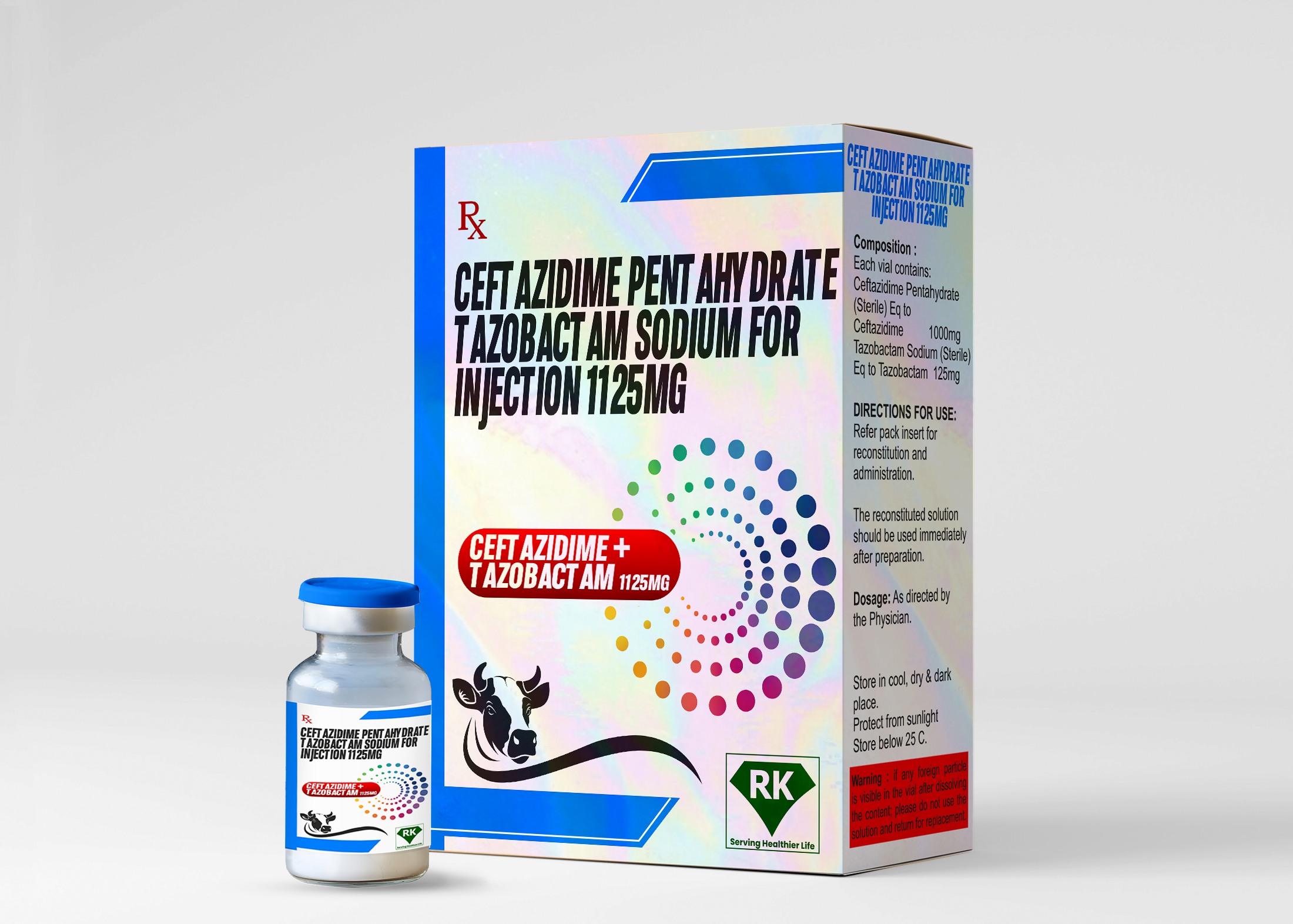

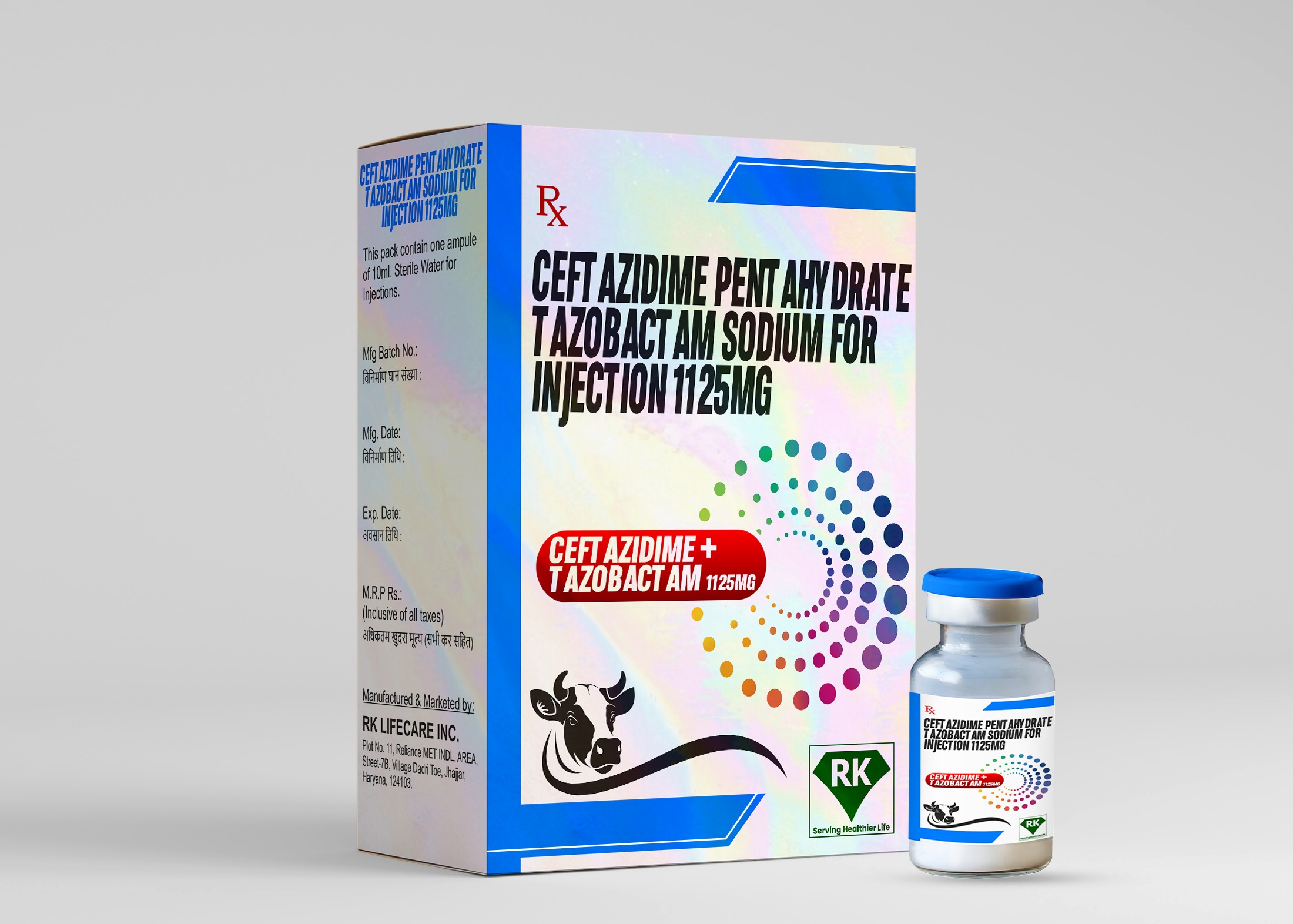

At R K Lifecare INC, We take immense pride in being one of the leading manufacturers and wholesalers of Ceftazidime Pentahydrate For Injection 1125mg in India. We are committed to providing high-quality injectable antibiotics that meet global healthcare standards, ensuring that patients in India and around the world receive effective treatments for various bacterial infections.

Our Ceftazidime Pentahydrate Injection is a third-generation cephalosporin antibiotic, widely used to treat severe infections caused by both gram-positive and gram-negative bacteria. Its broad-spectrum activity makes it an essential treatment option for patients suffering from conditions such as pneumonia, urinary tract infections, skin infections, and bloodstream infections.

As a Ceftazidime Pentahydrate Injection manufacturer in India, We produce this drug in compliance with the highest standards of quality, safety, and efficacy.

R K Lifecare INC is known for its strict adherence to Good Manufacturing Practices (GMP), ensuring that every vial of Ceftazidime Pentahydrate Injection 1125mg meets strict regulatory requirements. Our team of highly skilled professionals works diligently to ensure that the manufacturing process is executed flawlessly, from the procurement of raw materials to final packaging.

This attention to detail guarantees that our products are of the highest quality, meeting the expectations of healthcare providers, patients, and regulatory authorities. We take pride in being a trusted Ceftazidime Pentahydrate Injection wholesaler in India, ensuring that healthcare professionals across the country have reliable access to our products.

Our goal is to provide timely and consistent supply to Ceftazidime Pentahydrate Injection distributors in India and build long-term relationships with dealers, suppliers, and healthcare providers. With our established network of Ceftazidime Pentahydrate Injection suppliers in India, which also includes suppliers located in regions such as Delhi NCR, we ensure that the drug reaches patients in need.

Whether through Ceftazidime Pentahydrate Injection distributors in India or through dealers, we strive to meet the growing demand for high-quality injectable antibiotics that can effectively fight bacterial infections. By constantly improving our distribution channels and expanding our network, we ensure that the drug reaches healthcare providers in a timely and efficient manner, allowing them to provide patients with the best possible treatment options.

At R K Lifecare INC, We also produce Tazobactam 1125mg for Injection, a beta-lactamase inhibitor that is often combined with Ceftazidime Pentahydrate to enhance its effectiveness against resistant bacterial strains. As Tazobactam manufacturers for injection in India, we ensure that our products are developed with the same commitment to quality and safety that defines our Ceftazidime Pentahydrate Injection production process.

The combination of Ceftazidime Pentahydrate and Tazobactam is used to treat a wide range of infections, particularly those caused by multi-drug resistant bacteria. This combination therapy provides an essential tool for healthcare professionals in their fight against bacterial infections, making it an indispensable part of modern antimicrobial therapy.

Manufacturing Process of Ceftazidime Pentahydrate 1125mg for Injection

The process of manufacturing Ceftazidime Pentahydrate 1125mg for Injection involves several critical steps that ensure that the final product meets all the necessary safety and quality standards. Below, we provide a detailed look at the steps involved in our manufacturing process:

Procurement of Raw Materials

The production of Ceftazidime Pentahydrate Injection 1125mg begins with the careful selection and procurement of raw materials. As Ceftazidime Pentahydrate Injection manufacturers in India, we ensure that active pharmaceutical ingredients (APIs) and excipients are sourced from reputable suppliers that meet the required quality standards.

Our procurement process emphasizes the importance of traceability and transparency, and we only work with suppliers who provide certification for the purity and authenticity of their ingredients. After procurement, raw materials undergo thorough quality checks to confirm their suitability for use in the production process.

Quality Control (QC) of Raw Materials

Before any raw materials are used in production, they undergo rigorous quality control (QC) testing to ensure that they meet the specifications outlined by regulatory authorities. This includes testing for identity, purity, potency, and compliance with pharmacopeial standards. R K Lifecare INC, We have a dedicated QC team that ensures that every batch of raw materials meets the highest standards. Only those ingredients that pass these rigorous tests are approved for use in the production of Ceftazidime Pentahydrate Injection.

Formulation and Blending

The next step in the manufacturing process is formulation and blending. During this step, the Ceftazidime Pentahydrate API is mixed with excipients in precise proportions. This process must be done very carefully to ensure that the drug is evenly distributed throughout the solution.

Our experienced formulators use state-of-the-art blending equipment to ensure that the final solution is homogenous and stable. This step is critical to ensuring that each vial of Ceftazidime Pentahydrate Injection contains the correct amount of active ingredient, ensuring patients receive consistent and effective treatment.

Sterile Filtration and Filling into Vials

After the mixing process, the solution is subjected to sterile filtration to remove any particulate matter and ensure that the solution is free of microorganisms. This step is critical to maintaining the sterility of the injectable product. The filtered solution is then filled into sterile vials using an automated filling system. The exact amount of drug is filled into each vial, and the vials are sealed to prevent contamination. The entire process is performed in an aseptic environment to ensure the safety and integrity of the product.

Lyophilization (Freeze Drying) for Lyophilized Injection

For Ceftazidime Pentahydrate Injection 1125mg formulations that require lyophilization (freeze-drying), the next step is to freeze the solution and remove moisture through sublimation. This process helps maintain the stability and potency of the drug, as well as extend its shelf life.

Lyophilization is particularly useful for injectable formulations that need to be stored without refrigeration or that are heat sensitive. The lyophilized powder is then reconstituted before use, making it an essential method for maintaining the integrity of ceftazidime pentahydrate in some formulations.

Stoppering and Sealing

Once the vials are filled, they undergo stoppering and sealing. A rubber stopper is placed on each vial, and an aluminum seal is attached to keep the vials airtight and sterile. This step is important to prevent any external contamination during storage and distribution. The stoppers and seals are tested to ensure that they provide an effective barrier to prevent leakage or contamination.

Quality Control (QC) and Quality Assurance (QA) Testing

After the production process, Ceftazidime Pentahydrate for Injection 1125mg undergoes a final round of quality control (QC) and quality assurance (QA) testing. This includes testing for sterility, potency, pH levels, and other critical characteristics to ensure that the product meets all required specifications. Our QA team performs these tests in a controlled environment to verify that the product is safe, effective, and ready for use. Only after passing all these tests is the product approved for packaging and distribution.

Labeling and Packaging

The final step in the manufacturing process is labeling and packaging. We carefully label each vial with important information such as the product name, dosing instructions, storage requirements, expiration date, and safety warnings. Our packaging is designed to protect the product from physical damage and contamination during transportation. The packaging is also designed to be tamper-proof, ensuring that healthcare providers can rely on the integrity of the product.

Storage and Storage

Once the product is packaged, it is stored in our warehousing and storage facilities under controlled conditions. These facilities are designed to maintain proper temperature, humidity, and other environmental factors to ensure product stability. Proper storage is critical to maintaining the potency and effectiveness of the drug until it reaches the end user.

Distribution and Supply Chain

At R K Lifecare INC, We have developed an efficient distribution and supply chain network to ensure that Ceftazidime Pentahydrate for Injection 1125mg reaches healthcare providers and patients on time. Our distribution network is spread across India, including key areas such as Delhi NCR, which ensures that the product is readily available when needed. We work closely with Ceftazidime Pentahydrate Injection distributors and dealers in India to ensure that the product is delivered to the right locations, allowing healthcare providers to provide timely and effective treatment.

Uses and Side Effects

Ceftazidime Pentahydrate for Injection 1125mg is primarily used to treat bacterial infections, including infections affecting the respiratory tract, urinary tract, skin, and bloodstream. It is often used in combination with tazobactam to enhance its activity against resistant bacterial strains.

Like all medicines, Ceftazidime Pentahydrate Injection may cause side effects such as allergy, gastrointestinal discomfort or local reaction at the injection site. It is important for healthcare providers to monitor patients for any adverse effects and adjust treatment as needed.

At R K Lifecare INC, We are committed to producing high-quality injectable antibiotics that help improve patient outcomes. Through our dedication to quality manufacturing, strict quality control and reliable delivery, we strive to contribute to the global effort to fight infectious diseases and improve public health. By ensuring that our products are safe, effective and accessible, we are helping healthcare providers provide the best possible care to their patients.

14 Feb 2026

13 Feb 2026

12 Feb 2026

09 Feb 2026

07 Feb 2026