At R K Lifecare INC, We take great pride in our role as one of the leading Cefuroxime Sodium Injection manufacturers in India, specializing in the production and bulk distribution of Cefuroxime Sodium Injection 1000mg. Located in Delhi, India, our state-of-the-art manufacturing facilities and commitment to the highest standards of quality control make us a trusted name in the pharmaceutical industry.

Our Cefuroxime Sodium Injection has earned a reputation for excellence in treating a wide range of bacterial infections, from respiratory tract infections to urinary tract infections, skin infections, and much more. As one of the top Cefuroxime Sodium Injection wholesalers in India, we are dedicated to ensuring that our product is available to healthcare providers and institutions across India in need of a reliable and effective antibiotic treatment.

Cefuroxime Sodium is a third-generation cephalosporin antibiotic, renowned for its broad-spectrum efficacy against both gram-positive and gram-negative bacteria. This makes Cefuroxime Sodium Injection 1000mg an essential part of many treatment protocols, especially for infections where other antibiotics may fall short.

At R K Lifecare INC, We manufacture Cefuroxime Sodium Injection under strict quality control measures to guarantee both its safety and potency, ensuring that the drug remains effective in treating infections even in the most complex medical cases. We serve as a leading Cefuroxime Sodium Injection distributor in India, reaching healthcare institutions, hospitals, and clinics with a consistent and reliable supply of this vital drug.

As Cefuroxime Sodium Injection suppliers in India, we understand the importance of ensuring that Cefuroxime Sodium Injection in India remains accessible to those who need it most. The healthcare industry relies heavily on pharmaceutical companies to provide medicines that are not only effective but also available when needed.

Through our efficient distribution channels, we ensure that Cefuroxime Sodium Injection 1000mg is delivered to all parts of India quickly and reliably. We also prioritize transparency and communication with healthcare providers and distributors, ensuring they have access to the necessary information about the product's specifications, usage, and storage requirements.

Our manufacturing process for Cefuroxime Sodium Injection 1000mg is a multi-step process that requires careful attention to detail, precision, and adherence to good manufacturing practice (GMP). It begins with the procurement of high-quality raw materials.

At R K Lifecare INC, we source only the best raw materials from certified and reputable suppliers, ensuring we maintain the highest standards of purity and quality. From there, the raw materials undergo a rigorous process of manufacturing and blending, followed by sterile filtration and filling into vials, all in controlled environments that minimize the risk of contamination. This is especially important for injectable products, where sterility is of paramount importance.

Once the drug solution is prepared, the next critical step is lyophilization (freeze-drying) for lyophilized injections. This process preserves the stability and shelf-life of the product, ensuring it remains effective until ready for use. The vials of Cefuroxime Sodium Injection 1000mg are then sealed and sealed under strict quality control.

Before the product reaches the market, it undergoes additional rounds of quality control (QC) and quality assurance (QA) testing to confirm that it meets all regulatory and safety standards. After passing these tests, Cefuroxime Sodium Injection 1000mg is carefully labeled and packaged for distribution.

One of the key elements of our success as a wholesaler of Cefuroxime Sodium Injection in India is our robust distribution and supply chain process. We work closely with numerous Cefuroxime Sodium Injection distributors in India, ensuring that our product reaches healthcare providers in every region of the country. By maintaining a well-coordinated logistics system, we minimize delivery delays and ensure that hospitals and clinics have access to the medicine they need to effectively treat their patients.

Our warehouses are strategically located to handle large quantities of product and ensure timely delivery across the country. We also invest in state-of-the-art storage facilities that are designed to maintain the consistency of Cefuroxime Sodium Injection 1000mg, ensuring that the medicine is stored in optimal conditions throughout the distribution process.

At R K Lifecare INC, Our main mission is to manufacture and supply Cefuroxime Sodium Injection that meets the highest standards of quality and efficacy. Our experienced team, state-of-the-art manufacturing processes, and dedication to maintaining strict quality control ensure that our product is a reliable solution for healthcare providers across India.

We are proud to be one of the leading Cefuroxime Sodium Injection manufacturers in India and look forward to continuing our work in delivering life-saving medications to patients and healthcare professionals across the country.

Lyophilization (Freeze Drying) (For Lyophilized Injection Only)

The process of lyophilization (also known as freeze-drying) is an essential part of the production of Cefuroxime Sodium Injection 1000mg. Lyophilization is a technique used to preserve injectable medications by removing water from the drug solution through a controlled freezing and vacuum process.

This results in a dry powder that can later be reconstituted with a liquid before administration. Freeze-drying is particularly useful for maintaining drug stability over long periods of time, as it protects the active pharmaceutical ingredient from degradation caused by moisture.

For Cefuroxime Sodium Injection, lyophilization helps extend the shelf life of the product, ensuring it remains effective even after long periods of storage. The freeze-dried form also helps maintain the potency of the drug and prevents the formation of harmful byproducts that can occur when drugs are stored in their liquid state for long periods of time. By incorporating lyophilization into our manufacturing process, we ensure that Cefuroxime Sodium Injection 1000mg maintains the highest possible level of quality and effectiveness.

Stoppering and Sealing

Once Cefuroxime Sodium Injection 1000mg is lyophilized or filled into vials, the next step is stoppering and sealing. This process involves placing a rubber stopper on the vial and sealing it with an aluminum crimp cap. The stopper and seal help prevent contamination and ensure the sterility of the product. These steps are performed in a controlled, clean room environment to minimize the risk of any external contamination. The integrity of the stopper and seal is thoroughly checked to ensure that the vial is completely sealed and that no air, moisture, or contaminants can enter the vial.

This is important to maintain the sterility of the product and maintain its effectiveness. At RK Lifecare INC, we use high-quality materials for stoppering and sealing to ensure that Cefuroxime Sodium Injection 1000mg remains safe and reliable for use by healthcare professionals and patients.

Quality Control (QC) and Quality Assurance (QA) Testing

Quality Control (QC) and Quality Assurance (QA) processes are critical components of manufacturing Cefuroxime Sodium Injection 1000mg. At RK Lifecare INC, We conduct a series of QC and QA tests throughout the manufacturing process to ensure that each batch of Cefuroxime Sodium Injection meets the highest standards of quality and safety.

The QC process begins with testing raw materials to ensure that they meet the required purity and strength specifications. During production, the stability and quality of the drug solution is closely monitored, along with regular checks for sterility and contamination.

After the product is manufactured, it undergoes additional QC tests to ensure that it meets all regulatory requirements, including strength, stability, and safety standards. The final product is then subjected to QA reviews to confirm that all procedures and tests have been followed correctly, and that the product is safe and effective for patient use.

Uses and Side Effects

Cefuroxime Sodium Injection 1000mg is commonly used to treat a variety of bacterial infections, including respiratory tract infections (such as pneumonia and bronchitis), urinary tract infections, skin and soft tissue infections, and bone and joint infections. It is also used to treat infections caused by susceptible gram-positive and gram-negative bacteria. By inhibiting bacterial cell wall synthesis, cefuroxime sodium effectively inhibits bacterial growth, helping the body's immune system to clear the infection.

Like all medicines, cefuroxime sodium injection can cause side effects. Some common side effects include nausea, vomiting, diarrhea, and skin rash. In some cases, allergic reactions such as swelling, difficulty breathing, or anaphylaxis may occur.

Patients who are allergic to cephalosporin antibiotics or have a history of severe allergic reactions should not use Cefuroxime Sodium Injection without consulting their healthcare provider. It is important for healthcare professionals to monitor patients for any adverse reactions during treatment and adjust the dosage as needed.

Labeling and Packaging

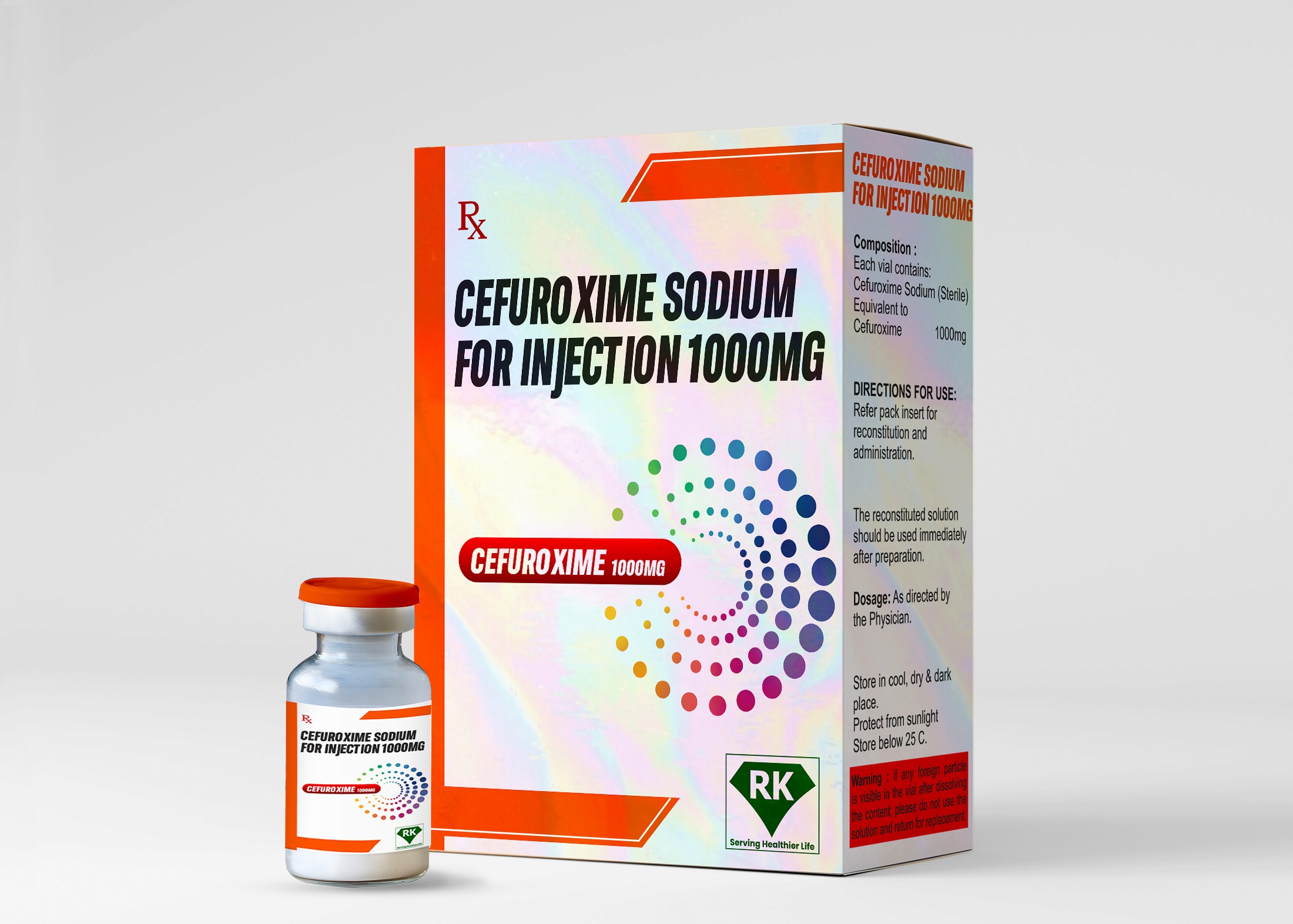

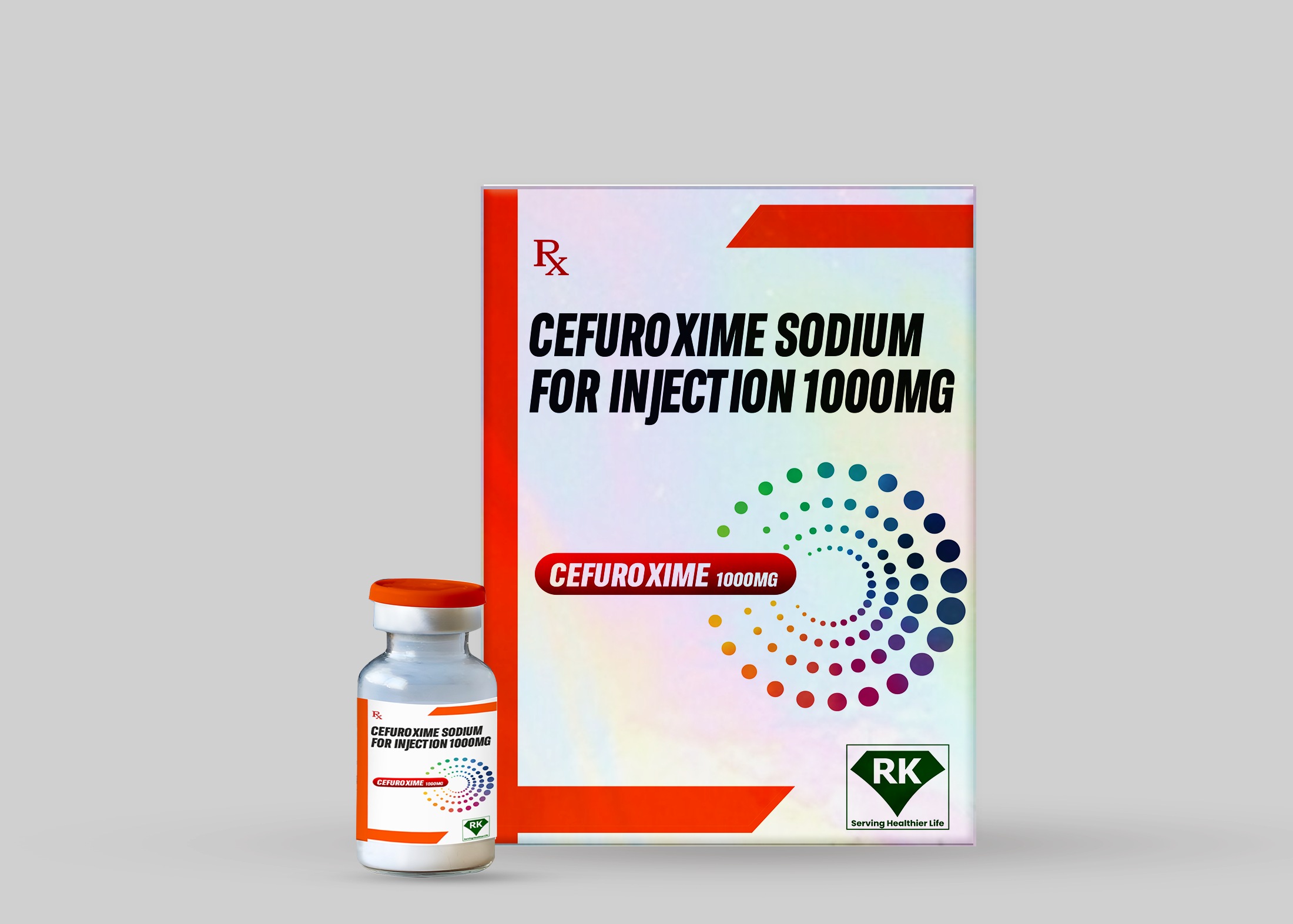

The labeling and packaging of Cefuroxime Sodium Injection 1000mg plays an important role in ensuring that the product is used safely and effectively. Essential information is clearly written on each vial, including the name of the drug, dosage, manufacturer's details, batch number, expiration date, and storage instructions. The packaging is designed to protect the product from external contaminants and physical damage, to ensure that it reaches healthcare providers in perfect condition.

Storage and Warehousing

Proper storage and warehousing are essential to maintain the quality and consistency of Cefuroxime Sodium Injection 1000mg. The product should be stored in a cool, dry place, away from direct sunlight and moisture. We use climate-controlled storage facilities to maintain the integrity of the product and ensure that it remains within the required temperature range throughout the distribution process.

21 Feb 2026

19 Feb 2026

17 Feb 2026

16 Feb 2026

14 Feb 2026